Terminology for Thermal Transfer Printing

Printing Process and Settings

Ribbon Sensor

This is the mechanism on the thermal transfer printer that uses an electronic eye to read the print field area on the label material. Some sensors utilize a gap between labels in order to identify light. Other sensors require a timing mark or a hole punch on the back of the liner.

Dots Per Inch (dpi)

dpi is a measure of the resolution of a printed document or digital scan. The higher the dot density, the higher the resolution of the print or scan. Typically, dpi is the measure of the number of dots that can be placed in a line across one inch, or 2.54 centimeters. When it comes to Monitors, they do not have dots, but pixels. The closely related concept for monitors and images is pixels per inch (ppi).

Inches per second (IPS)

IPS stands for inches per second. It is for the print speeds at which thermal transfer printers image.

Ink Melting Point

The temperature in a thermal transfer printer that melts the ribbon ink into the face sheet.

Burn Temperature

The varying heat settings that transfer the ribbon ink to the face sheet. Some materials require a higher burn setting to transfer the ink.

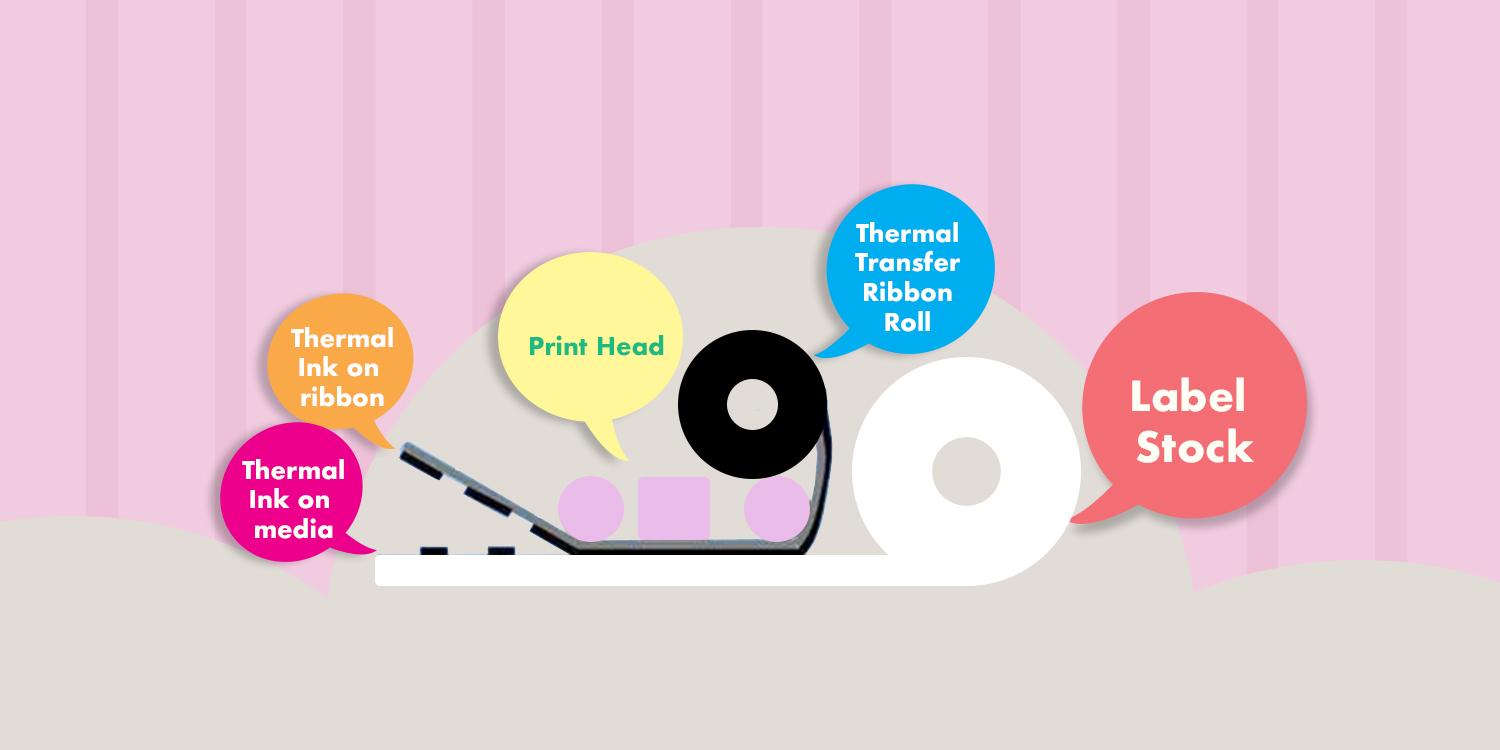

Printhead

Electronic thermal transfer printing element using individually energized matrix wires to transfer the image from the ribbon to a substrate.

Printing Result and Defects

Printability

Printability refers to surface characteristics on the face stock that relate to printing quality. It is an indication of which face stocks are best for the desired print quality.

Feathering

Feathering is a printing defect. It is characterized by uneven, ragged print edges, or by ink spray around the print edges.

Ghosting

Ghosting is the indistinct ghost-like images caused by poor ink distribution, label surface inconsistency, ribbon inconsistency or ribbon/label incompatibility.

Guard Bars

A pair of bars, which furnish reference points for scanning devices, found at the beginning, middle and end of U.P.C., and EAN symbologies.

Haloing

Haloing is when a shadow inadvertently appears around the entire printed image, or around its leading edge. It is caused by excessive pressure on the printing surface.

Void

A void refers to the absence of ink in a printing area where ink should appear. Voids create an area of white space that can interfere with the first-read rate of a printed code, and depending on the size and location of the area, may render the code unreadable.

Type of Thermal Transfer Printing

Flathead and Near Edge Printing

For barcode ribbon printing, the coated side contacts with the label, while the uncoated side transfer the heat to the ribbon and passes over the print head. The heat transfers the ink from ribbon to label. There are two kinds of printhead technologies utilized in current thermal transfer ribbon printing, i.e. Flathead and Near Edge. They all offer increased efficiencies, while there are obvious differences.

Flathead printer is a heating-elements center-located horizontal printhead. As ribbon passes through the heating-elements, ink is dispatched to the substratum. This time the ribbon and substrate travel horizontally to the front of the printer. Then the ribbon is separated from the substratum and directed to the take-up spindle. The flathead printhead is fixed. You can choose wax ink ribbons, wax/resin ribbons or resin black/color ribbons. The flathead printing speed is 14 ips (inches per second). The popular flathead printers are Zebra, Sato, Honeywell, TSC, Datamax, etc.

Near-edge printer is a heating-elements edge-located 45 degree angled printhead. Near-edge printhead is also called floating head or corner edge. This technology provides fast printing speed (up to 40 ips) and automatically adjusts to the media thickness (up to 14 point). A lot of different media (such as magnetic tape, heat shrink, plants pens, etc) should be specified for the special applications. The unique ribbon chemistry limits ribbon type to wax/resin and resin black and color thermal transfer ribbon formulations. The common near-edge printers are Toshiba TEC and Novexx for tag and label printing, and Markem and Videojet for printing directly on to flexible packaging (TTO Thermal Transfer Overprint).

Thermal Transfer Overprinter (TTO)

TTO is perfect for flexible packaging and typically use near edge technology. TTO is used for imprinting expiration dates, lot codes, barcodes, and text and images. The usages include snack foods, packaged produce, meats, medical devices, pharmaceuticals, etc. TTO can print at speed of 18 - 24 ips and some higher volume TTO can print up to 40 ips. TTO is a technology that creates messages in resolutions up to 300 dpi by pushing a ribbon into contact with a substrate using a printhead. The printhead is made up of a series of miniature print elements under a ceramic coating and a layer on the thermal printer ribbon is covered with a colored wax and/or resin mixture. The mixture on the ribbon melts as small areas of it come into contact with the elements that are heated, this transfers and adheres color to the surface of the substrate as it moves under the printhead. The unique design of Wolfbarco TTO products delivers a clean and user-friendly operation, ideal for coding on a range of substrates including plastic films, flat packaging, label stock, plastic and foil. Please contact us, we would be happy to help your business grow.

Desktop thermal printers

They usually use flathead technology. Since desktop printers are much smaller and lighter than tabletop printers, they are typically used for lower volume applications, such as retail, healthcare and point-of-sale. Desktop printers run at lower speeds and need less adjustments. Mobile thermal printers use direct thermal technology. Direct thermal printer does not require ribbons, the ink is in the label material.

Other types printers

There are different types of thermal printers. Tabletop thermal printers are used as industrial printers for industrial and manufacturing printing applications. They are the largest and most heavy duty of all thermal transfer printers. The advantage of tabletop printers is to produce high volume printing at top speeds. They are either flathead or near edge print heads. Tabletop thermal printers also use many different types of paper, labels, tags, etc. Near-edge printing is normally used for high caliper stocks.