Direct Thermal Printing vs Thermal Transfer Printing

The Short Story

The difference between thermal transfer and direct thermal

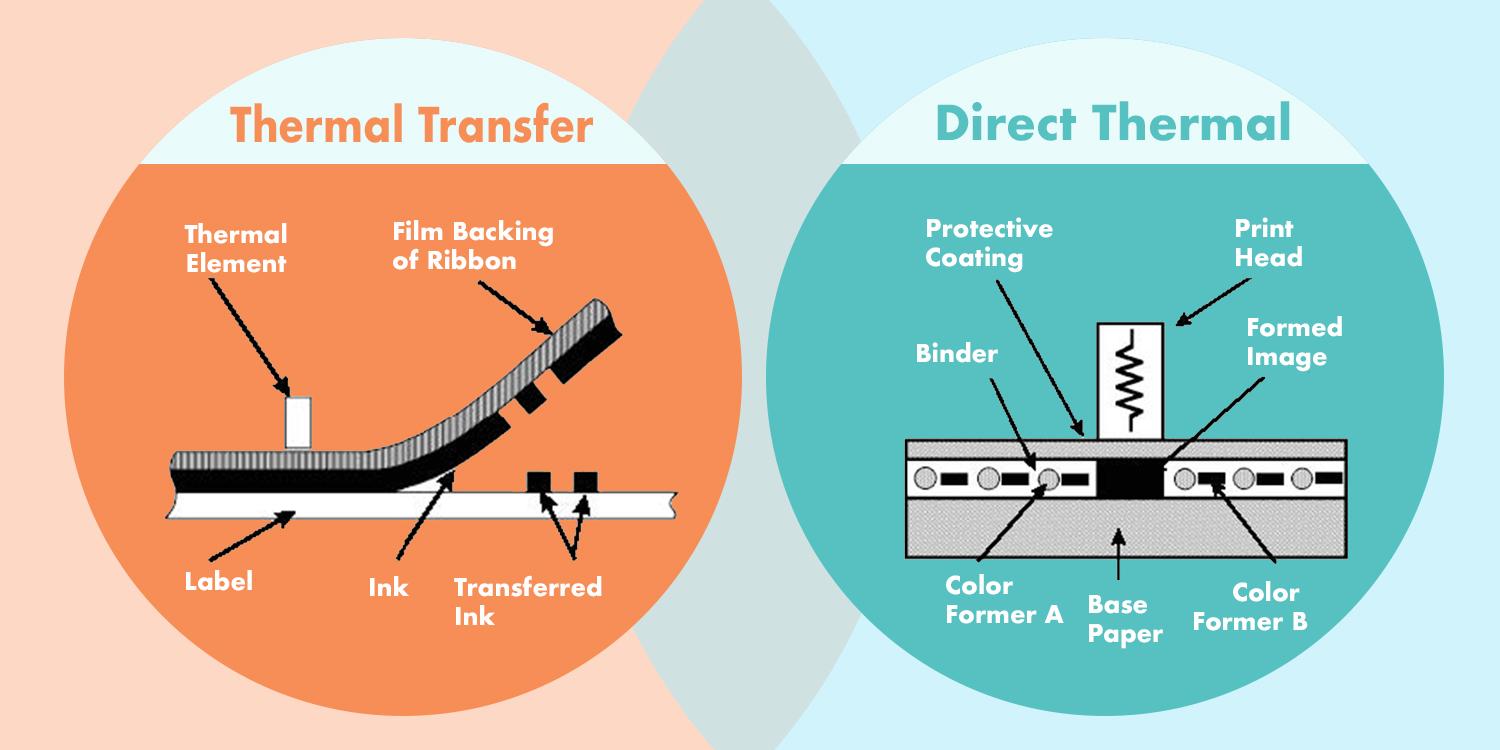

First and foremost, let's understand the fundamental difference between direct thermal printing and thermal transfer printing. In simplest terms, thermal transfer printing utilizes a thermal ribbon to print while direct thermal printing does not. Yes, it is that simple. For thermal transfer printing, you will need to have both label stock and thermal transfer ribbon. But for direct thermal printing, you only need heat-sensitive label in order to print.

The label life requirement as the key consideration

When choosing the correct technology for your business, one of the most important considerations is whether you need your label to have a long-lasting life or not.

If you only need a label to last for a few hours or a few days in an indoor environement, most likely direct thermal printing will statisfy your need. If you need the label to last beyond a few days or the lifetime is undetermined and the label wil be exposed to light and in an outdoor environement or cold and chemical abrasion in specical handling, you will need thermal transfer printing.

In this article, we will explore in detail the pros and cons of Direct Thermal Printing and Thermal Transfer printing so you can make an informed decision.

Direct Thermal Printing

If you need to print receipts, tickets, visitor or patient identification, that doesn't require lasting for a long time, you can use direct thermal printer to do the job. There are a number of benefits of using direct thermal printer.

Benefits of Direct Thermal Printer

- Low cost and durable. The investment of direct thermal printer is usually lower compared to thermal transfer printer.

- Light weight and easy to use. A direct thermal printer usually just weighs a few pound. Its portability allows you to carry it anywhere your application needs it to be. Because there is no ribbon needed. All you need is to load the label stock and print.

- Low maintenance (no ink/toner, no ribbon). It is easy to maintain, since there is no ink, no toner and no ribbon. The only supply you need is the direct thermal material.

Limitations of Direct Thermal Printers

Direct thermal printing has its own limitations. Make sure you understand throughly all the cons before you decide if direct thermal print truly fits your application.

- Direct thermal printed labels have short shelf life. The printout images may fade quickly over time. The images are very sensitive to heat, light or water. The printout images is easy to be rubbed

- Reduced Print Head Life. Direct thermal printing requires the print head elements be in direct contact with the label material as it is pulled across the print head. As a result, the label material is in direct and constant contact with the print head, resulting in increased wear when compared to thermal transfer printing. Generally speaking, a company should anticipate direct thermal print heads providing an expected lifetime of 25% - 50% of a thermal transfer print head.

Thermal Transfer Printing

If your label needs to last for a long time, or will be exposed to heat, light and subjected to abrasion, or the information on your label is extremely critical, you will need to use thermal transfer printer to print your labels.

Thermal transfer printer is designed to print high quality labels that can last a long time for clear and unique identification. Comparing with the direct thermal printer, the thermal transfer print head heats a ribbon, which transfers wax or resin to the media. This technology ensures the printout stay a long time. That is why many industries adopt the thermal transfer ribbon printer for their applications of warehouse management, packaging, shipping, retail stores, medical identification and so on.

Benefits of Thermal Transfer Ribbon Printing

- Barcode are guarantied for the quality and durability

- Ribbon can be paper, polyester or polypropylene

- Any asset tags or IDs can be printed

- Endure temperature/chemical exposure or sterilization

Limitation of Thermal Transfer Ribbon Printer

- Cost is higher than direct thermal printer

- Knowing the right ribbon goes with the right label

- Ribbons need to be changed on a regular time frame

- Keep printhead clean is the part of routine work